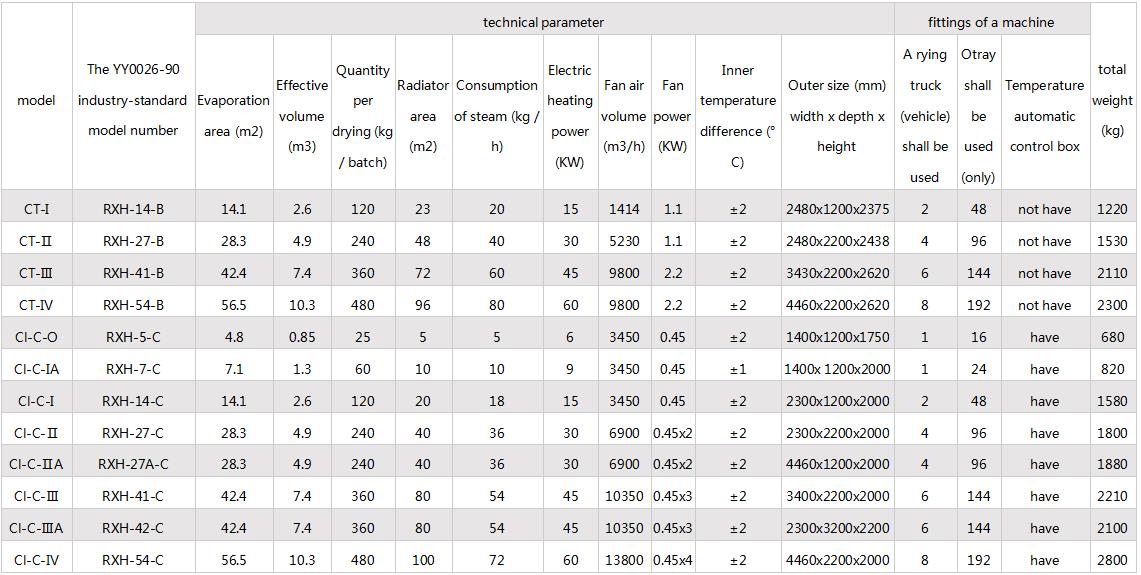

Hot air circulation oven, after multiple upgrades and replacements, has reached the domestic and international level; The CT series is a substitute product with an average thermal efficiency of about 30%, using a centrifugal fan, external circulation of the box, and manual temperature control.

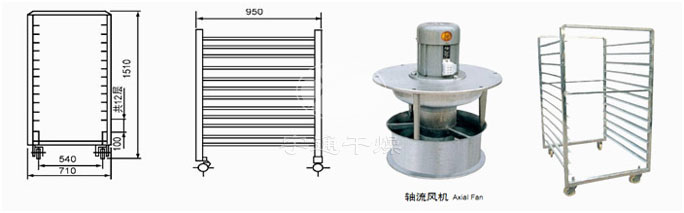

After multiple modifications, the CT-C series oven has been formed, which all uses axial flow fans, is equipped with an automatic constant temperature control system, and has a backup computer control system for selection. The thermal efficiency reaches about 70%. It uses steam or electric heat sources to heat the air through convection heat transfer in the heat exchanger using an axial flow fan. The hot air flows laminar through the drying plate and transfers heat to the material. Continuously replenishing fresh air and continuously expelling humid and hot air to ensure appropriate relative humidity inside the oven. The major feature of this series of ovens is that some of the hot air circulates inside the oven, and the entire circulation process is enclosed, thereby enhancing heat transfer and saving energy.

1, wide range of application, can dry a variety of materials, is a universal drying equipment.

2, most of the hot air in the box circulation, high thermal efficiency, energy saving.

3, the use of forced ventilation, the box is equipped with adjustable air distribution plate, the material dry evenly.

4, the heat source can be steam, thermal oil, hot water, electricity, far infrared, etc., wide selection.

5, wide range of application, can dry a variety of materials, is a universal drying equipment.

6, wide range of temperature application, according to user requirements, up to room temperature to 350℃

7. The machine has low noise, balanced operation, temperature control, easy installation and maintenance.

This series of hot air circulation ovens is a universal drying equipment with a wide adaptability, widely used for heating, curing, drying and dehydration of materials and products in industries such as pharmaceuticals, chemicals, food, light industry, and heavy industry. Such as raw materials, herbal medicines, traditional Chinese medicine decoction pieces, powders, granules, granules, packaging bottles for small and large honey pills, pigments, dyes, dehydrated vegetables, dried fruits and vegetables, sausages, plastic resins, electrical components, baking paints, etc.

1, the heating heat source has steam, electricity, far infrared, electric vapor dual use, for users to choose.

2, the use of temperature: steam heating 50-140℃, up to 150℃.

3, electricity, far infrared temperature 50-500℃.

4, equipped with automatic control system and computer control system for users to choose.

5, commonly used steam pressure 0.02-0.8Mpa(0.2-8kg/cm).

6, with electric heating, according to type I calculation 15KW, practical 5-8kw/h.

7. Special requirements are explained when ordering.

8, non-standard oven price negotiable.

9, the use of temperature greater than 140 ° C or less than 60 ° C, to be indicated when ordering.

10, the factory factory drying car, drying tray size is uniform, can be interchangeable.

11, drying pan size: 460×640×45mm.

Studio size: according to user requirements of any size design;

Temperature parameters: Design according to the user's required temperature range, temperature uniformity and other technical indicators;

Structure type: integral, assembled;

Heating type: electric heating, oil heating, gas heating, steam heating, mixed heating;

Hot air circulation mode: according to the different placement of baked products, choose a reasonable hot air circulation mode, (such as side blast single cycle, top blast double cycle, large circulation before and after the blast, etc.;

Door opening mode: front door, front door, top door, lifting door;

Workpiece conveying mode: trolley type, roll type, plate chain type, mesh belt type, push rod type;

Car drive mode: manual, blunt pinion rack drive, traction car drive, hoist drive, roll row drive;

Temperature control mode: digit digital display instrument temperature control, time proportional temperature control instrument temperature control, domestic intelligent (program) temperature control instrument temperature control imported intelligent (program) temperature control instrument temperature control.

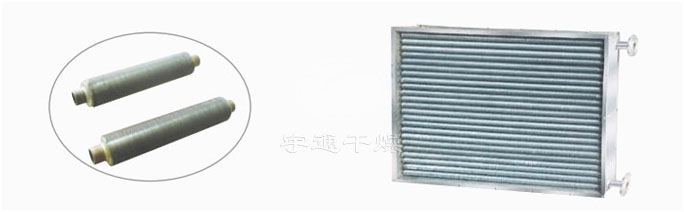

It can be used with various drying equipment with different specifications. The materials used include aluminum alloy, stainless steel, A3 steel surface coated with zinc, steel aluminum composite, steel, and steel pipe aluminum winding. In addition, the radiator can be used separately for indoor and warehouse heating and dehumidification, and our factory can design and manufacture it for users.

Material: Stainless steel, A3 steel

Material: Stainless steel, rust proof aluminum alloy.

1, heating heat source steam, electricity, far infrared, electric steam dual purpose;

2, commonly used steam pressure: 0.02-0.8Mpa(0.2-8kg/cm2)

3, with electric heating: 15kw(according to CT-C-1 calculation), practical 5-8kw/h;

4, the use of temperature: steam heating 50-140℃, up to 150℃; Electricity, far infrared 50-350℃;

5, equipped with automatic control system and computer control system for users to choose;

6, the factory drying car, drying tray size is uniform, can be interchangeable;

7, the use temperature is greater than 140 ° C or less than 60 ° C, when ordering instructions;

8. Various special requirements are indicated when ordering.