The SMH series double door drying and sterilization oven is suitable for sterilizing penicillin bottles, ampoules, aluminum caps, metal and glassware in the pharmaceutical industry, removing heat sources, and drying and sterilizing solid materials. Widely used in industries such as pharmaceuticals, chemicals, light industry, food, electronics, etc. for dry or sterile production.

The SMH series double door drying and sterilization oven control system is sensitive, equipped with programmable controller PLC human-machine interface touch screen, micro differential pressure meter, automatic moisture removal valve and flammable gas concentration test proposal for special environment, and a batch of key parts are all made in Japan, the United States and Taiwan, China, China. The quality of the oven is guaranteed. The complete hundred level laminar flow purification system meets the requirements of GMP standards.

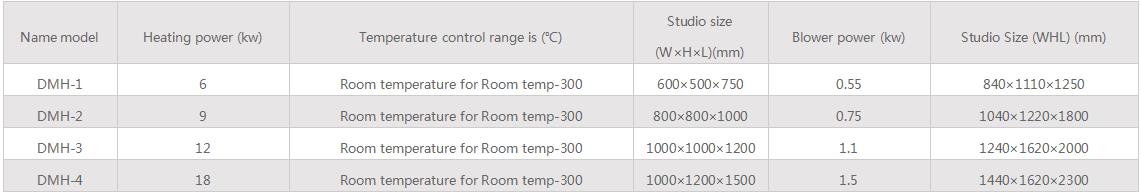

The SMH series double door drying and sterilization oven is available for users to choose from, and its configuration and size can also be customized according to the user's equipment usage, site, production capacity, etc.

Place the drying tray, bottle, or cart filled with materials into the box, start the PLC programmable control system, and the internal circulation fan will work, heat up, and the butterfly valve will open simultaneously. The drying box will quickly heat up. Under the action of the internal circulation fan, dry and hot air enters the box through a high-temperature resistant filter, and forms a uniform distribution of air under the action of the fine adjustment plate to be transmitted into the box. The dry air absorbs the moisture on the surface of the bottle (material, item), enters the heating channel for evaporation and discharge, and the dry air flows directionally under the action of the fan, while the water vapor is discharged. As the water vapor gradually decreases and fresh filtered air is intermittently replenished, the box is in a slightly positive pressure state, the constant temperature ends, and the process control is completed. Turn on the air supply or (inlet) forced cooling, the automatic butterfly valve enters the closed state, and the sound and light prompt opens the door to release the bottle.

Previous :SG series tunnel type hot air oven

Next:none!